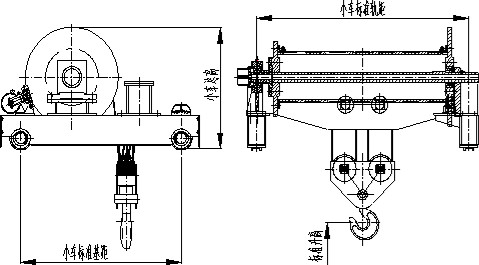

GBM hoisting mechanism

More》

Lifting motor: low speed and high torque motor is independently designed and manufactured by GBM; the lowest rotation speed is one turn/every ten minutes and speed regulation ratio is 1:300, this is higher than European crane 1:10 by 30 times;

Electronic control system: it is independently developed by GBM. Aiming at performance features of low speed and high torque motor, the company breaks through key technology of direct-drive crane under condition without reduction box, and develops world-leading control function of crane such as light load and speediness, operation at dead slow speed, distance inching and error correction and provides new functions and tools for meeting requirements of high speed handling of materials and precise assembly at ultra-low speed, which can greatly improve working efficiency of crane.

Performance comparison form between GBM crane and European and traditional cranes

(Taking QD200t/50t-33m H=28m A3 as an example)

| Contents for comparison | GBM crane | European weight-reduction crane | Domestic traditional standard crane |

|---|---|---|---|

| Working class | It can adjust and protect for A3-A8. | It can adjust for A3-A7, without protection. | It cannot adjust and protect for A3-A8. |

| Transmission mode | Simple | Complex | Complex |

| Wide range of speed regulation | Speed range is from 0.1 to 90m/min, speed regulation ratio can achieve 1:300 | 1:10 (maximum: 1:15) | Speed is not adjusted; 1:10 can be realized if frequency converter is added. |

| Light load and speediness | According to real-time weight, light load and speediness can be realized at section of constant power and secondary hook is canceled. | It cannot be realized. | It cannot be realized. |

| dead slow speed operation | Start dead slow speed operation function, control speed to be less than 0.2m/min. Accurate positioning can be realized, this can prevent too operation speed and avoid repeatedly positioning and avoid load knocking and scratch. | It cannot be realized. A few imported cranes have similar optional function, but performance cannot reach level of Gongbu. | It cannot be realized. |

| Distance inching | Start Distance inching function, set inching distance to be 1 to 3mm each time. This can guarantee steady load operation and realize high-precision positioning. It is especially suitable for maintenance and precise assembly of large mechanical equipment. | Distance inching cannot be realized. Inching causes impact. | Distance inching cannot be realized. Inching causes impact. |

| Synchronous control | Synchronous control of two sets or more of drive mechanisms can be realized. | Optional function, synchronous device needs to be added. | Optional function, synchronous device needs to be added. |

| Flexible startup and brake and zero-speed brake | Protect and prevent load from impact, prolong service life of crane steel structure and brake and other parts. | Zero speed brake cannot be realized. | All cannot be realized. |

| Multiple security protected mode | Safety brake and electromagnetic safety protection device. Even if safety brake fails, it also can protect load and avoid stalling and gliding. | If safety brake fails, object will stall and fall. | If safety brake fails, object will stall and fall. |

| Motor starting, without impulse current | Starting current is not more than work current of rated load, this can prolong service life of electricity and save investment of bus. | Starting current is 2 to 3 times of current of rated load. Frequent impact affects service life of electricity and operation of other equipments of same circuit and investment of bus will be big. | Starting current is 2 to 3 times of current of rated load. Frequent impact affects service life of electricity and operation of other equipments of same circuit and investment of bus will be big. |

| Efficient system and obvious energy saving effect. | Electricity is saved generally by more than 20%. Motor can run four-quadrant. Energy feedback can be realized, feedback efficiency is high, with good quality, meeting requirements of connecting network. | Compared with traditional one, it can save some electricity, but realized feedback efficiency is low and quality is poor. | Not save electricity |

| Start under load does not fall | It does not fall. | It falls a little. | It falls. |

| Self-learn with empty hook | Self-learn under load without needing to dismantle motor; self-learning parameter is accurate and is convenient to commission at the site. | Crane motor must be separated from reduction box before self-learning under load. It is not convenient for site commissioning. | Crane motor must be separated from reduction box before selfe-learning under load. It is not convenient for site commissioning. |

| “internet+” new function | Many functions such as crane work visualization, data collection, remote diagnosis, remote control, multi-machine linkage, unattended production line and seamless joint of production line can be realized. | Advanced European crane can realize. | It can not be realized. |

| Reserving function upgrading interface | Functions such as communication fault protection, automatic positioning, anti-sway and presetting action can be upgraded. | Reserving function interface cannot be realized. | Reserving function interface cannot be realized. |

[Lifting speed]: When one crane works, lifting speed of GBM trolley is variable value. The lighter the actual lifting tonnage is, the faster the lifting speed is. Light-load speed is lifting speed to which light load corresponds; heavy-load speed is corresponding lifting speed under heavy load. When actual lifting weight is rated load, the speed can be calculated according to reference hoisting power. Lifting speed adopts frequency control; speed regulating scope is 0.2m/min, corresponding to marked lifting speed.

[Running speed] horizontal moving speed of GBM hoisting trolley at span direction of crane, the value in selection table is common speed; it also can be separately designed according to requirements of users, adopting frequency control.

[Total height of trolley]: distance from track surface of trolley to the highest point of trolley.

[trolley base distance]: it is trolley wheelspan, it is recommended value in selection table and actual value can be adjusted according to need of working condition.

[trolley gauge]: Distance between running tracks of trolley. Trolley gauge in selection table is minimum gauge under corresponding type and can be increased according to hoisting requirements; when selecting, try to select gauge which can better match with actual parameter of whole machine.

[lifting height]: it is distance between hook center and ground when hook hoisting reaches highest point; standard lifting height in selection table is minimum height under corresponding type, which can be increased according to the facts.

[light-load fast speed]: When actual load is less than rated load, light-load fast speed (speed range: 110 to 250% of rated load) can be achieved, specific value shall be designed according to requirements of users.

[stalling protection]: when actual load is less than or equal to 50% of rated load, it can be achieved as standard-configuration function. When actual load is bigger than 50%, to achieve stalling protection, it needs to be used as optional function.

Steps for selection

Step 1

Selecting work level: types listed in selection album include work levels such as M3, M5, M6 and M7, which will be selected according to actual work of crane. In case of other work level or other special working condition (such as M4 and M8), when you don’t know how to choose by reference to catalogue, please contact with Gongbu Machinery for your selection service.

Step 2

Selecting lifting weight: according to work level, choose corresponding lifting weight according to selection table.

Step 3

Selecting lifting speed: after meeting work level and lifting weight, select lifting speed according to actual needs (Lifting speed is normally determined according to lifting height and needs).

Step 4

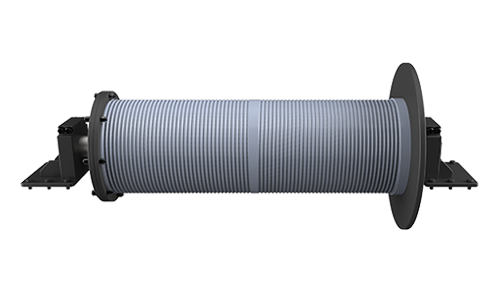

Selecting lifting height: in selection table, corresponding lifting height of each type is minimum lifting height; try to select lifting height being close to actual value. If actual lifting height is more than height in selection table, it can be achieved through lengthening drum but must be clearly marked in selected type. Under the situation of many types meeting, try to select type with smaller gauge.

Step 5

Select total height of trolley: after selecting corresponding type, total height of trolley of selected type shall be used in total height of crane for further verifying, check whether to meet high limit of whole machine. Please contact with Gongbu Machinery for special requirements.

※Notes

1. When collaborative operation of main and secondary hooks is not needed, secondary hook will be canceled, speed changing range of because lifting speed can reach 300 times, and can fully achieve small-tonnage efficiently running.

2. Selection data in sample is given in the form of GBM overall trolley parameter. If users want to separately purchase GBM lifting mechanism , data for needed GBM lifting mechanism is still in the table.

3. Users can design and calculate steel member such as main beam according to maximum wheel pressure of trolley, standard base distance of trolley and gauge of trolley. If weight of trolley or other parameters are needed, please consult according to actual condition parameters. We list following trolley weight of common tonnage standard for your reference:

| Rated hoisting weight | 50t | 80t | 100t | 125t | 160t | 200t | 250t | 300t |

| Trolley weight | 7.28t | 10.36t | 12.3t | 13.2t | 24.9t | 27.6t | 29.88t | 34.7t |

Hoisting and trolley gauge can be adjusted. Value listed in sample is standard reference value. They need to be separately designed according to actual work conditions.

5. Please specify if you need special customizing in control.

| Rated hoisting weight (t)(t) | GBM hoisting trolley type | Rate | Lifting speed (m/min) light-load(m/min) | Lifting speed (m/min) full-load | Standard operation speed (m/min) | Standard gauge of trolley (mm) | Standard lifting height (mm) | Total height of trolley (mm)) | Standard base distance of trolley (mm)(mm) | Maximum reference wheel pressure of trolley (KN) | Recommended track for trolley |

|---|

Rated hoisting weight (t)(t) | GBM hoisting trolley type | Rate | Lifting speed (m/min) light-load(m/min) | Lifting speed (m/min) full-load | Standard operation speed (m/min) | Standard gauge of trolley (mm) | Standard lifting height (mm) | Total height of trolley (mm)) | Standard base distance of trolley (mm)(mm) | Maximum reference wheel pressure of trolley (KN) | Recommended track for trolley |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 10 | 3010114 | 4 | 0.2-7 | 0.2-4 | 0.1-35(超过此速度,可按客户要求另行设计) | 2000 | 15 | 750 | 2300 | 30.6 | P18或方钢40x40 |

| 10 | 3010213 | 4 | 0.3-7.8 | 0.3-5.2 | 0.1-35(超过此速度,可按客户要求另行设计) | 1800 | 15 | 820 | 2300 | 30.8 | P18或方钢40x40 |

| 10 | 3010215 | 3 | 0.3-10 | 0.3-6 | 0.1-35(超过此速度,可按客户要求另行设计) | 2000 | 15 | 820 | 2300 | 31.4 | P18或方钢40x40 |

| 10 | 5010216 | 3 | 0.3-10 | 0.3-6.6 | 0.1-35(超过此速度,可按客户要求另行设计) | 2000 | 15 | 750 | 1250-1650 | 31.4 | P18或方钢40x40 |

| 10 | 5010218 | 3 | 0.3-10 | 0.3-7.5 | 0.1-35(超过此速度,可按客户要求另行设计) | 2200 | 15 | 820 | 1250-1650 | 31.6 | P18或方钢40x40 |

| 10 | 5010314 | 2 | 0.3-10 | 0.3-9.5 | 0.1-35(超过此速度,可按客户要求另行设计) | 2000 | 15 | 820 | 1250-1650 | 31.8 | P18或方钢40x40 |

| 10 | 6010219 | 3 | 0.3-10 | 0.3-7.7 | 0.1-35(超过此速度,可按客户要求另行设计) | 1800 | 15 | 750 | 1250-1650 | 30.8 | P18或方钢40x40 |

| 10 | 6010311 | 3 | 0.3-12.5 | 0.4-9.5 | 0.1-35(超过此速度,可按客户要求另行设计) | 2300 | 15 | 820 | 1250-1650 | 31.4 | P18或方钢40x40 |

| 10 | 7010220 | 3 | 0.3-10 | 0.3-7.7 | 0.1-35(超过此速度,可按客户要求另行设计) | 2300 | 15 | 820 | 1250-1650 | 41.3 | P24、P30或扁钢50x30 |

| 10 | 7010312 | 3 | 0.3-12.5 | 0.4-9.5 | 0.1-35(超过此速度,可按客户要求另行设计) | 1800 | 15 | 1030 | 1250-1650 | 43 | P24、P30或扁钢50x30 |

d

1.Standard configuration of lifting mechanism

F level insulation otor over-temperature protection

2. Electronic control

IP55 protection level.

3. Brake

- Standard-configuration panel type brake has better and safer braking effect.

- Zero-speed braking, service life of brake can be greatly prolonged.

- Built-in electromagnetic brake can avoid power losing, stalling and avoid dust, without asbestos friction sheet.

Standard function of lifting mechanism

1. Speed ratio is more than 1:50 and less than 1:300, speed range is from 0.1m/min to 90m/min (according to configuration of selection table).

2. Light-load fast speed (according to configuration of selection table).

3. Running at dead slow speed. 0.2m/min

4. Microspur inching. Inching distance is 3mm each time.

5. Synchronous control: one set of control system can control two sets of driving mechanisms at the same time, achieving synchronous operation of two machines.

6. Flexible starting, flexible braking, zero-speed braking, protecting load from being impacted and prolonging service life of parts such as steel structure of crane and brake.

7. Security protection pattern. Motor stopping protection, safe brake protection and built-in electromagnetic brake, under the situation that load is not more than 50% of rated load, it can realize safe and special protection of power losing.

8. Start current has no strike, and is not more than rated current of motor.

9. Self-learning with empty hook. Self-learning with load without needing to remove motor; self-learning parameter is accurate, which solving the problem that crane motor and reducer must be separated for self-learning for many years, and facilitates site commissioning;

High-configuration options of hoisting trolley

1. Design and manufacture according to speed ratio and speed range needed by users at 1: 300 speed ratio, within speed range of 0.1m to 90m/min.

2. Light-load fast speed, with permitted range of security, design and manufacture according to needs of users; light-load fast speed and heavy-load slow speed.

3. Running at dead slow speed: it can achieve 0.1-0.2m/min

4. Microspur inching: inching distance of each time can be realized by 1 to 3mm.

5. Synchronous control, one control system can control many sets of driving mechanisms at the same time and realize synchronous operation of many machines.

6. Security protection customizing. Under the situation of rated load, stalling protection can be realized.

7. Energy feedback can be realized, with high feedback efficiency and good quality, meeting requirement of network accessing.

8. Functions of data collecting, remote diagnosis and remote control.

9. Automatic positioning function

10. Communication fault protection

11. Work visualizing

12. Anti-sway

13. Automatic positioning function

14. Smart management system of work level

15. Unattended operation for production line

National service hotline: 0795-7776606

Emali:gongbujx666@163.com

Fax: 0795-7776268

Address: No. 223 of Yaodu North Avenue of Zhangshu city of Jiangxi provinc

MEMBER

MEMBER PRODUCT INQUIR

PRODUCT INQUIR  TECHNICAL SUPPORT

TECHNICAL SUPPORT DOWNLOAD CENTER

DOWNLOAD CENTER

Document Download

Document Download